After long time tests, our new high TG resin temperature 255° carbon clincher rims are ready now.

When heating go up to 200 degree, our resin still at 79% solid. When heating go up to 230 degree as what most of you can achieve on mountain, our resin can still keep 64% solid.

TG255° rim raw finish (basalt brake track).

TG255° rim ud black matt (3k twill brake track)

We offered basalt and 3k twill brake track, both are come with high TG resin temperature 255°, pretty good for the riders often do long time hard/ prolong braking. We will do more tests on the basalt and 3k twill brake track. Our goel is to solve the heating problem under all riding condition!

It's not ready for mass production yet, because the curing takes too long, max 5 rims only for one mold, so the cost is crazy expensive with this process. We will make more molds of 38mm and 50mm depth for climbing market firstly.

Update: Since the rim doesn't have over heating issue, we do many brake tests to compare the brake power of rim with basalt brake track and 3k twill brake track in the dry and wet conditions.

We suggest to use 3K twill brake track, work with our

special pad, for best brake power both on dry and wet conditions.

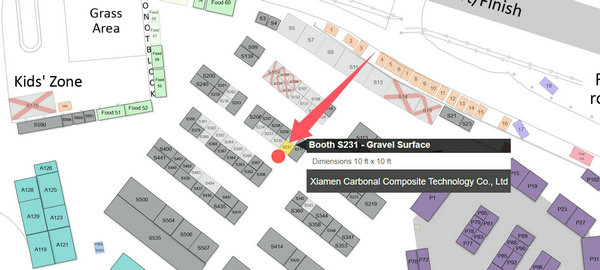

+86-592-578 6546

+86-592-578 6546 info@carbonalbike.com

info@carbonalbike.com English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português 日本語

日本語 한국의

한국의 Polski

Polski